Almost one third of the German population needs to take medicine every day. One out of four people in Germany regularly take three or more types of medications at the same. These patients’ pill dispensers are piled high with different pills for each day of the week.

It can be difficult to determine the correct dosage or intake, especially for those who are older or have cognitive impairments. The answer could be to manufacture pills individually for each patient. These pills would include all of the necessary medication and reduce the number pills needed to be taken each day to one.

Scientists at Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) and the Bavarian Laser Centre (blz) are now researching a potential manufacturing process for such customized pills—3D printing. Their findings have been published in the journal Additive Manufacturing.

The concept of 3D Printing is well-known in the industry. It allows customized components and tools from a range of materials to be quickly manufactured. This process is important for medicine as it allows the production of custom-made implants and prosthetics, hearing aids, and dental prosthetics.

This is not all. Research is being conducted on the use of 3D printers to manufacture medications. It is clear that the advantages of 3D printing are numerous, as it allows for different active ingredients to be combined and also tailors dosage to meet patients’ daily needs. The treatment could become more individual, safer and less complex.

New layer, new active ingredient

FDM printing is a technique that was used in the past to apply active ingredients layer by layer using a nozzle, much like cream on cake. This method does not allow for the creation of fine structures in the pills. Researchers have developed a new way to manufacture such pills in a joint project with FAU, blz University College London, and University of Santiago de Compostela.

Three active ingredients were first mixed in powder form, including paracetamol (a pain reliever) and caffeine. They then added a non-active carrier powder. The ingredients are layered thinly and then placed under a powerful laser to melt them into a compact tablet.

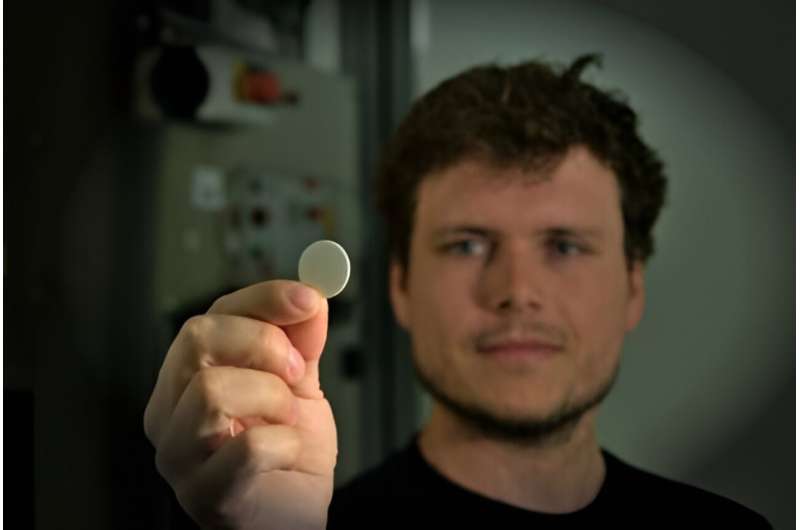

Sebastian-Paul Kopp is the project leader. “Our new manufacturing technique uses gentle processes for active ingredients, and allows us to use conventional Laser beam sources.” The FAU method does not require the use of absorbent particles to control the laser energy.

“Furthermore we can adjust not only the combination of active ingredient for each pill but also for every layer of a tablet.” Kopp explains that this allows him to control when a specific active ingredient is released.

The research on a customized drug is still at an early stage. One day, our local pharmacies may be able to print medication for millions of patients quickly and easily, customized to their exact needs. This is currently in the works.

For more information, please visit:

Sebastian-Paul Kopp and colleagues, Electrophotographic 3-D printing of pharmaceutical films Additive Manufacturing (2023). DOI: 10.1016/j.addma.2023.103707

Friedrich–Alexander University Erlangen–Nurnberg

Citation:

Printing pills using a 3D Printer (2023, 10/6)

Retrieved 6 October 2023

from https://medicalxpress.com/news/2023-10-pills-3d-printer.html

This document is protected by copyright. This document is protected by copyright.

No part of the website may be reproduced or copied without written permission. Content is provided solely for informational purposes.