Steel 3D printing is coming to area because of a brand new customized steel 3D printer designed by Airbus for the European House Company (ESA) that’s now aboard the Worldwide House Station. To not be confused with the polymer-based 3D printers used on the ISS utilizing plastic supplies, that is the true deal – “steel being melted utilizing a laser.”

The primary steel 3D printer for area, picture credit score: Airbus.

VIEW GALLERY – 3 IMAGES

The ESA’s steel 3D printer was despatched to the ISS aboard the Cygnus NG-20 resupply mission and may very well be a game-changer for each the Worldwide House Station and area exploration as we all know it. With the power to 3D print steel, spare elements and even model new ones may very well be successfully ‘manufactured’ in orbit with out counting on rockets and resupply missions.

3D steel printing could be very completely different from utilizing plastic, with the chrome steel wire of this practice printer heated as much as a 1,400 levels Celsius melting level in comparison with 200 levels Celsius for plastic wire.

“Steel 3D printing represents a better technical problem, involving a lot larger temperatures and steel being melted utilizing a laser,” ESA technical officer Rob Postema mentioned. “With this, the security of the crew and the Station itself should be ensured – whereas upkeep potentialities are additionally very restricted. If profitable although, the energy, conductivity and rigidity of steel would take the potential of in-space 3D printing to new heights.”

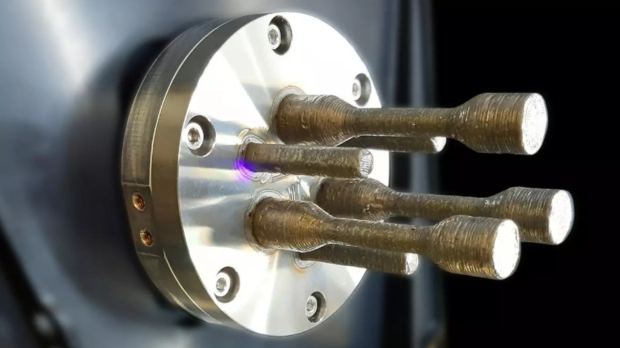

One of many first steel 3D specimens to be printed on board the ISS, picture credit score: ESA

The printer will function in a totally sealed field designed to stop extra warmth or fumes from reaching the crew of the ISS. As soon as fired up, the printer’s inside oxygen is vented into area after which changed by nitrogen, as sizzling chrome steel would oxidize if uncovered to oxygen. As a take a look at, the printer will start by creating “4 fascinating shapes,” which is able to take two to 4 weeks to print. The explanation for the prolonged period comes all the way down to noise rules on the ISS, with the printer described by the ESA as “comparatively noisy.”

The primary prints might be packaged and despatched again to Earth for evaluation.

“This expertise demonstration, showcasing the processing of metallic supplies in microgravity, paves the best way for future endeavors to fabricate infrastructure past the confines of Earth,” Thomas Rohr, ESA Supplies and Processes Part, mentioned.

“It is a leap for innovation in area exploration,” Patrick Crescence, venture supervisor at Airbus, provides. “It paves the best way for manufacturing extra advanced metallic constructions in area. That may be a key asset for securing exploration of the Moon and Mars.”