Ford Motor Firm has leveraged SLA and SLS 3D printers from Formlabs to prototype a number of elements for its new Electrical Explorer SUV.

The world’s sixth-largest automotive producer, Ford beta-tested Formlabs’ latest 3D printer, the Kind 4, to streamline its automotive design course of. This added to its current Formlabs Kind 3L and Fuse 1+ 30W methods.

The corporate used 3D printing to prototype designs for key elements of its new electrical SUV, together with mirrors, handles, charging ports and dashboard elements. This has reportedly allowed the workshop crew to take extra dangers, unlock complicated designs, and rapidly prototype new design iterations in hours quite than days.

By streamlining its design course of with additive manufacturing, Ford hopes to ship on its dedication to providing a wholly electrical car (EV) lineup in Europe by 2030. The pace of 3D printing is reportedly important to assembly this tight timeframe.

“If we didn’t have entry to additive manufacturing, we might not be capable to compete with the rivals, we might not be capable to be so quick,” defined Bruno Alves, Additive Manufacturing Professional and Tooling Specialist at Ford.

“Additive manufacturing is essential within the improvement course of. It provides you the chance to provide elements in a short time, very effectively, and cut back prices,” added Sandro Piroddi, Supervisor of the Speedy Know-how Middle at Ford.

Ford leverages Formlabs’ new Kind 4

Ford’s PD Merkenich Speedy Know-how Middle is the automotive producer’s improvement facility, chargeable for designing all passenger autos for the European market. Right here, SLS, SLA, FDM and metallic 3D printers have lengthy performed a task in producing car prototypes.

Notably, resin 3D printers from Formlabs are taking part in a key function in designing Ford’s newest vary of EVs, together with the Electrical Explorer SUV. SLA 3D printers are primarily utilized in workshops to design prototypes that require a high-quality floor end. These elements additionally should be produced rapidly to allow fast iterations.

Ford turned one of many first corporations to undertake the Kind 4, Formlabs’ latest MSLA 3D printer.

Launched earlier this 12 months, the Kind 4 gives high-speed 3D printing, reliability, and high quality materials properties. Its accelerated print speeds are a big differentiator from its predecessor, the Kind 3+. The brand new resin 3D printer can full normal print jobs in beneath two hours and boasts vertical speeds of as much as 100 mm/hr.

“The Kind 4 may be very quick, I feel it’s the greatest machine that I’ve seen till now by way of pace. It’s actually an excellent improve in comparison with the earlier fashions,” commented Alves. “It’s simpler to function, so it’s a lot simpler for the operators in our workshop to learn to work with the machine and get elements with good high quality.”

Piroddi referred to as the Kind 4 a “recreation changer” due to its quick 3D printing speeds, permitting Ford’s improvement crew to extend throughput and obtain extra design flexibility. The crew can now fulfil extra requests in beneath 24 hours and ship in a single day shipments of elements to the UK.

SLA 3D printing has performed a key function in validating the design of many exterior and inside elements for the brand new Ford Electrical Explorer. Formlabs’ Kind 3L, a large-format SLA 3D printer, was used to 3D print huge exterior elements in a single piece. This included the rear-view mirror cap, the charging port cowl, and dashboard options.

SLS 3D printing streamlines electrical car prototyping

Ford additionally operates a big suite of SLS 3D printers to check mechanical automotive elements, together with Formlabs’ Fuse 1+ 30W, which may 3D print PA-12 nylon materials. This possesses properties which might be similar to the injection molded mass manufacturing elements.

The corporate was additionally one of many first to beta-test Formlabs’ Fuse Blast automated cleansing and sprucing system. That is stated to have accelerated Ford’s prototyping course of by eradicating the necessity for handbook post-processing.

A key benefit of SLS expertise is that it doesn’t require help buildings, permitting it to 3D print extra complicated designs. As such, the Fuse 1+ 30W was used to provide numerous mechanical elements and assemblies for the brand new Explorer. This included the electrical SUV’s complicated charging port, which reportedly couldn’t have been prototyped with every other manufacturing technique.

“It’s a very complicated design that we’re not in a position to produce in every other means. We can’t mill this half. We can’t use injection molding to provide just a few samples,” said Alves. “So one of the best ways is to print in a cloth that we will check bodily.”

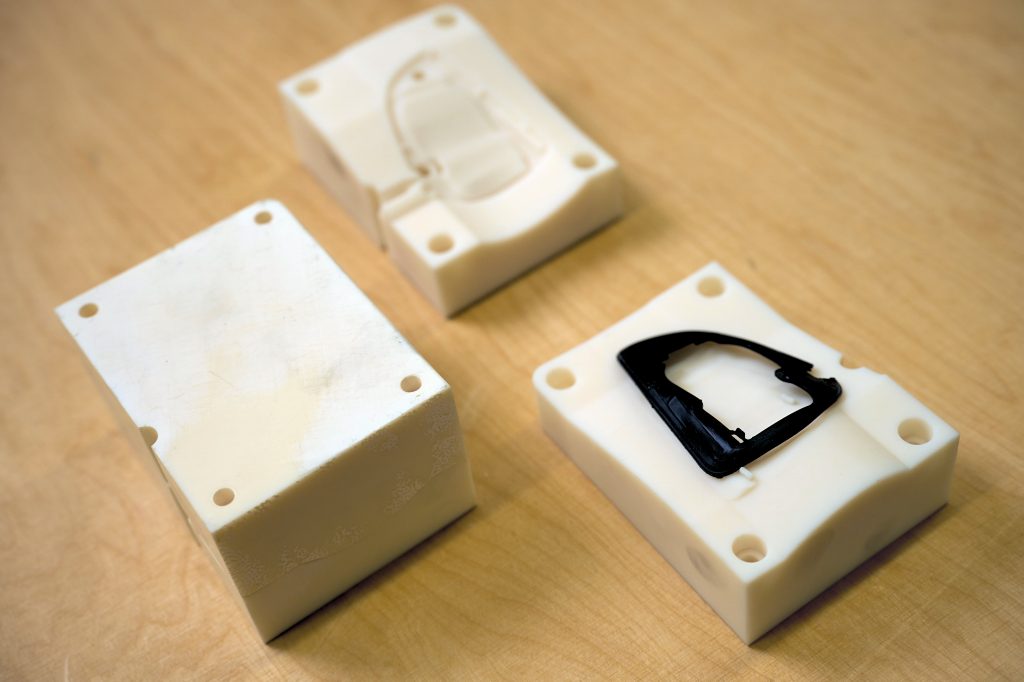

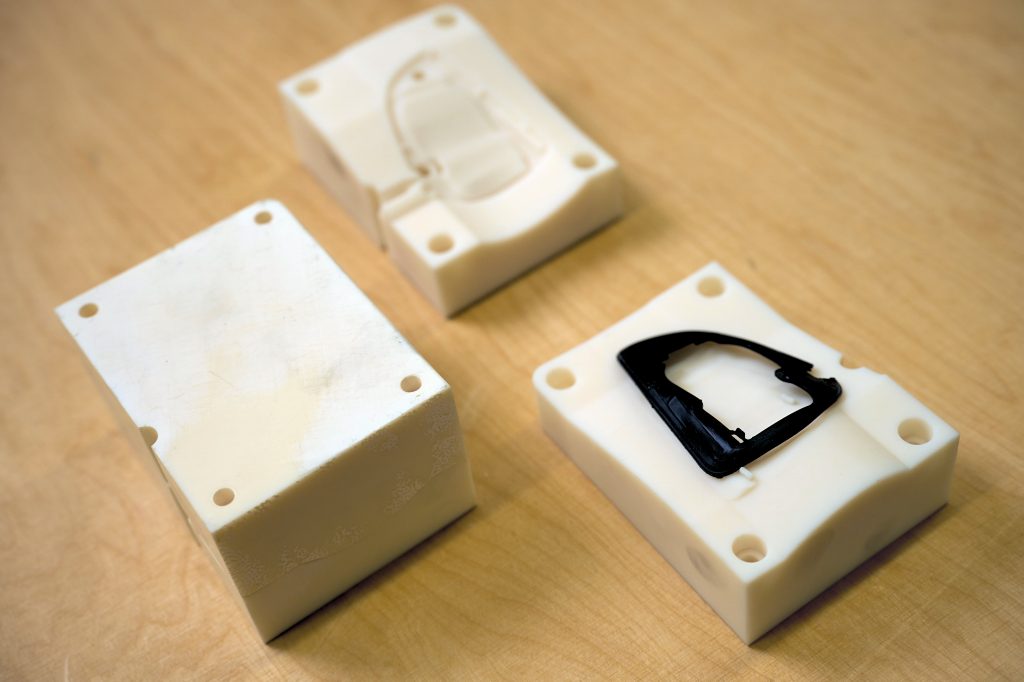

3D printing unlocks in-house injection molding

Ford has additionally mixed conventional manufacturing processes with 3D printed speedy tooling. This permits the crew to find out and choose essentially the most appropriate manufacturing course of and materials for various functions, chopping prices and rising workflow effectivity.

In car crash assessments, elements have to be constructed from the identical materials and course of because the mass-produced last half. Plastic elements are usually produced by injection molding, which normally requires expensive and time-consuming metallic tooling.

“We see loads of potential utilizing 3D printing inserts for injection molding based mostly on the truth that we will iterate the design very quick. We print cavities in cores after which we will change them within the device and inject the elements,” added Alves.

For the brand new Explorer, Ford produced rubber elements for the SUV’s door deal with meeting in-house utilizing 3D printed mould inserts. Exterior injection molding usually takes two to 3 months. Nonetheless, by additively manufacturing the inserts in-house, Ford can full this course of in beneath three weeks. The crew 3D printed the mould inserts in Inflexible 10K resin on their SLA 3D printers, and Nylon 12 Powder on SLS.

“For this challenge, if we had to make use of exterior instruments, it will have been rather more time-consuming and we might not have been in a position to ship the elements on time,” defined Alves.

Additive manufacturing for automotive functions

Ford isn’t the one automotive producer integrating additive manufacturing into its design and manufacturing workflow.

Final 12 months, World industrial 3D printer producer INTAMSYS partnered with printing supplies provider KEXCELLED to offer FDM 3D printing capabilities to the Automotive Division of SIKA in China.

By 3D printing automotive elements, SIKA has seen time and value financial savings of as much as 90% for its automotive prototyping and improvement phases. INTAMSYS’ 3D printing expertise has additionally been leveraged to provide inside and exterior automotive equipment, together with custom-made bumpers, steering wheel check items, racing automotive elements, and tail brand fixtures.

Elsewhere Japanese automotive multinational Toyota has beforehand adopted the Zortrax M300 Plus to 3D print meeting jigs and fixtures. Adopting the FDM 3D printer has reportedly optimized its car meeting operations, decreasing prices and lead instances behind manufacturing important instruments and spares.

Toyota’s devoted 3D printing labs, based mostly of their Polish facility, have put in greater than 100,000 zł ($23,000) price of Zortrax gear. The elements at present 3D printed on the plant fall into 4 classes: positioning jigs, meeting jigs, meeting instruments, and covers. These elements are sometimes mixed with different elements produced utilizing subtractive processes to kind built-in assemblies.

Wish to assist choose the winners of the 2024 3D Printing Business Awards? Be part of the Professional Committee at present.

What does the way forward for 3D printing maintain?

What near-term 3D printing tendencies have been highlighted by business specialists?

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the newest 3D printing information.

You too can comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture exhibits the brand new Ford Electrical Explorer. Photograph through Ford Motor Firm.