French metallic additive manufacturing firm AddUp and German aerospace firm MT Aerospace have prolonged their partnership on Directed Power Deposition (DED) know-how. The extension of this partnership contains the acquisition of a second Module 400 machine by MT Aerospace.

Additive manufacturing programs based mostly on DED know-how, vary from Laser Steel Deposition (LMD) also called laser cladding, blown powder DED, and commerce names corresponding to Laser Engineering Internet Form (LENS). Materials, in both wire or powder type, is reworked from stable to liquid state by way of centered vitality, for instance, an electron beam, laser, or in some circumstances a plasma arc.

The DED print head is mounted on a gantry, very like FFF/FDM, and strikes throughout the construct chamber to deposit materials. Along with the vitality supply and materials, the print head may additionally present a shielding gasoline to take care of an inert ambiance across the soften pool.

The extension of this partnership contains the acquisition of a second Module 400 machine by MT Aerospace. These two DED machines will allow MT Aerospace to multiply initiatives whereas shortening industrialization instances, enabling the corporate to maneuver extra rapidly towards sequence manufacturing of this know-how.

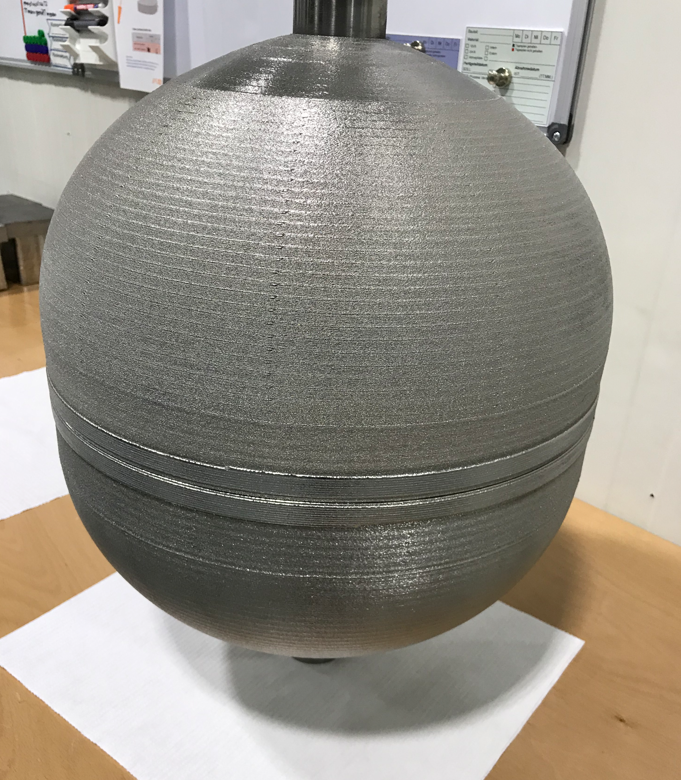

For the previous two years, AddUp has labored carefully with MT Aerospace specialists to qualify functions by way of the DED course of. The Modulo 400 machine, which consists of a vibration powder dispenser for stability and reliability within the powder provide of the deposition nozzle, can produce components with advantageous floor finishes and superb mechanical properties. MT Aerospace says it has efficiently examined it on a variety of supplies, because of an enclosure inerting machine, which permits working with reactive powders corresponding to titanium.

MT Aerospace and AddUp profit their prospects by way of their prolonged partnership

MT Aerospace is planning to construct a complete industrial platform based mostly on DED know-how in simply two years, with design capabilities in addition to manufacturing, post-processing, and half inspection capabilities. All of those actions, in accordance with the corporate, will likely be later suitable with the specs of the EN 9100 commonplace related to the aerospace sector.

With the addition of a second Modulo 400 3D printer, MT Aerospace claims it has improved its understanding of the DED course of. Consequently, the corporate will likely be able to using the doubled manufacturing capability to work in a number of instructions on the similar time. Firstly, in partnership with the European House Company, the qualifying phases for satellite tv for pc gas tanks will likely be accelerated, as will the event of contemporary functions for satellites and micro-launchers. Secondly, this second machine will provide an opportunity to develop providers and thus deal with different industries corresponding to automotive or vitality.

MT Aerospace claims it has already “succeeded in convincing a number of principals of curiosity” within the DED course of and is now relying on this new AddUp machine to enhance the anticipated rise in manufacturing volumes within the years forward. AddUp is aiding this progress by permitting its shoppers from Germany and past to learn considerably from MT Aerospace’s experience in incorporating the DED course of.

How industrialization is scaling additive manufacturing

Beforehand, Multinational automotive producer BMW introduced the profitable completion of its Digitalisation and Industrialisation of Additive Manufacturing or ‘IDAM’ undertaking. Since its inception 4 years in the past, BMW and its companions have established two digitally enabled automotive 3D printing manufacturing strains. These manufacturing suites, one in Bonn at materials developer GKN Powder Metallurgy and the opposite in Munich, are able to producing round 50,000 components annually whereas functioning autonomously with out the need for handbook enter.

Moreover, Siemens opened its Charlotte Superior Expertise Collaboration Hub (CATCH) to assist prospects speed up their plans for additive manufacturing industrialization. This analysis and growth facility is positioned in Charlotte, North Carolina, and is led by Siemens Digital Industries, Siemens Expertise, and Siemens Power. To additional industrialize 3D printing within the area, the hub will collaborate with key OEMs, end-users, and US nationwide laboratories.

“We’re excited to launch this new additive manufacturing hub and to start inviting prospects in to collaborate and discover methods to speed up the industrialization of this know-how,” mentioned Tim Bell, Additive Manufacturing Enterprise Supervisor at Siemens Digital Industries. “The advantages of additive manufacturing are clear from quicker time-to-market, to higher design by way of digital prototypes, to localized manufacturing serving to to cut back provide chain constraints.”

Comply with this hyperlink for all of the Formnext 2022 information.

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Business e-newsletter or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you in search of a job within the additive manufacturing trade? Go to 3D Printing Jobs for a number of roles within the trade.

Function picture reveals Module 400 machine. Picture by way of AddUp.