Although meals 3D printing might not have but satisfied all meals lovers, it definitely has raised its justifiable share of questions. For instance, is a meals 3D printer wholesome? Can it enhance the way in which we eat and reply to the numerous diets and constraints of shoppers? With a purpose to reply all these questions, a workforce of mechanical engineers from Columbia has been conducting a number of exams and experiments of their Artistic Machines Lab, led by Professor Hod Lipson. And their newest undertaking is a 3D printed cheesecake, composed of a number of layers, 7 to be exact. This cheesecake was made to be able to display the advantages of the expertise, notably when it comes to meals customization but additionally meals security and monitoring of ingested vitamins.

Jonathan Blutingler, a post-doctoral fellow within the lab and lead contributor to this new undertaking, sought to display the advantages of meals 3D printing, a course of that continues to be controversial right now. Many view 3D printed meals as unappetizing and the expertise as a gimmick that will have little impact. Discussing a few of the obstacles the expertise nonetheless faces in addition to its clear advantages, he expanded, “As a result of 3D meals printing continues to be a nascent expertise, it wants an ecosystem of supporting industries reminiscent of meals cartridge producers, downloadable recipe recordsdata, and an setting wherein to create and share these recipes. Its customizability makes it notably sensible for the plant-based meat market, the place texture and taste have to be fastidiously formulated to imitate actual meats.”

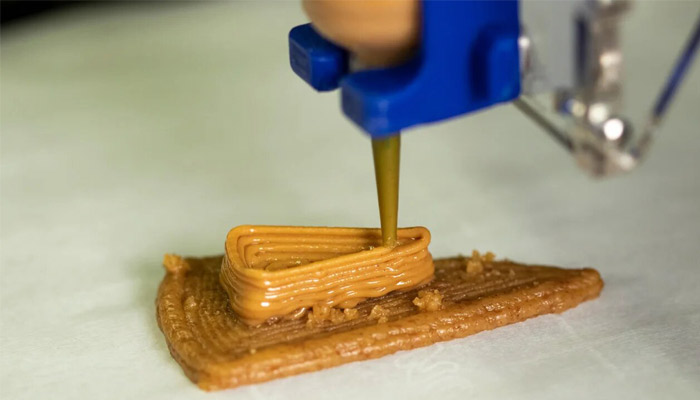

Peanut butter on the graham cracker (photograph credit: Jonathan Blutinger/Columbia Engineering)

To design this 3D printed cheesecake, the workforce first needed to flip all of the substances into dough. They used graham cracker, peanut butter, Nutella, banana puree, strawberry jam, cherry drizzle, and frosting, all of which had been bought at a New York grocery retailer. A number of print exams had been carried out to find out which order was greatest to print which ingredient. For instance, the graham cracker was the meals that carried out greatest as the primary printed layer, in all probability resulting from its adhesion to the machine tray. Peanut butter and Nutella, alternatively, are extra appropriate as intermediate layers to assist softer supplies reminiscent of jam. The workforce in the end in contrast the design of this 3D printed cheesecake to that of a constructing, with structural components supporting extra fragile components.

This cake was not 3D printed to revolutionize the very idea of baking, however extra to indicate that meals 3D printing might present higher management over what’s on our plates. Certainly, Professor Christen Cooper from Tempo College Vitamin and Dietetics and a contributor to the undertaking, explains, “We have now an infinite downside with the low-nutrient worth of processed meals. 3D meals printing will nonetheless prove processed meals, however maybe the silver lining shall be, for some folks, higher management and tailoring of diet–personalised diet. It might even be helpful in making meals extra interesting to these with swallowing issues by mimicking the shapes of actual meals with the pureed texture meals that these sufferers–hundreds of thousands within the U.S. alone–require.”

By with the ability to add meals very exactly, in chosen and measured locations, the meals 3D printer might create new culinary experiences the place the patron might select precisely what he needs to eat. So, fantasy or actuality, that’s the query: one factor is bound, solely time will inform! Within the meantime, you’ll find extra data HERE.

What do you consider this 3D printed cheesecake? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t overlook to join our free weekly Publication right here, the most recent 3D printing information straight to your inbox! You too can discover all our movies on our YouTube channel.

*Cowl Photograph Credit: Jonathan Blutinger/Columbia Engineering