You’ll be stunned by the quantity of authentic and delicate jewellery designs which are doable at present utilizing 3D printing, for instance a hoop with 7,801 diamonds! One participant within the subject is Cloud Manufacturing unit, an organization shaped by professionals from totally different sectors that come collectively to assist artists, creators, manufacturers, avid gamers for the event of actual jewellery because of additive manufacturing. With simply an concept the crew takes care of the design, 3D modeling, sending samples, packaging of your jewellery ordered along with your model emblem … all with out the necessity for a minimal order, or stock issues. We interviewed them to search out out extra about their firm and their manufacturing of distinctive silver jewellery in a sustainable means.

3DN: Might you introduce your self and clarify your hyperlink with additive manufacturing?

We’re a crew of very totally different folks coming collectively from very totally different fields. Our founder Taavi has been working within the subject of additive manufacturing for over a decade now – growing working programs for FDM 3D printers and instructing college students and fellow startups the advantages of 3D printing. Marek, the co-founder, has a PhD in powder metallurgy and earlier than diving into the world of startups, he labored as a scientist at TalTec College in Tallinn to unravel totally different issues with industrial 3D printers. I, Kati, the one feminine founder, labored in one of many largest and oldest nightclubs within the Baltics as a advertising supervisor, coping with totally different artist brokers and promoters and holding updated with every little thing that the younger folks within the membership like and are thinking about. I even have a level in inventive entrepreneurship specializing in vogue design. And Erik joined us from the world of cryptocurrencies, funding gold and affiliate internet marketing. Collectively we completely lined all of the features that our rising enterprise desperately wanted. Taavi was probably the most intrigued by additive manufacturing and the methods it could possibly be used to actually showcase the advantages of this expertise.

The Cloud Manufacturing unit crew

3DN: How did the Cloud Manufacturing unit journey start?

Taavi, by likelihood, met a worldwide celebrity who escaped from the US to have a quiet retreat within the forests of Estonia, away from the paparazzi. Taavi was very excited to have the ability to create some steel jewellery gadgets for him and, along with Marek, they obtained a authorities innovation grant and developed quick, high-quality parameters for the college’s industrial 3D printer. Then, Taavi requested me to hitch the crew to assist with branding, advertising and design. I instantly noticed higher potential for this enterprise than simply with this celebrity he met, and from there we began making samples for artists coming to carry out on the nightclub I labored for and likewise for different artists visiting Estonia, utilizing contacts from my days working within the leisure subject. We shortly noticed the amazement within the artists’ eyes once we introduced them with necklaces and rings with their logos and design components. This enterprise mannequin instantly gained them over, so we determined to increase the enterprise from having a product retailer to not having our personal gross sales channels and changing into a “white label” manufacturing service for a lot of artists, influencers and jewellery manufacturers.

3DN: How do you make the 3D printed jewellery?

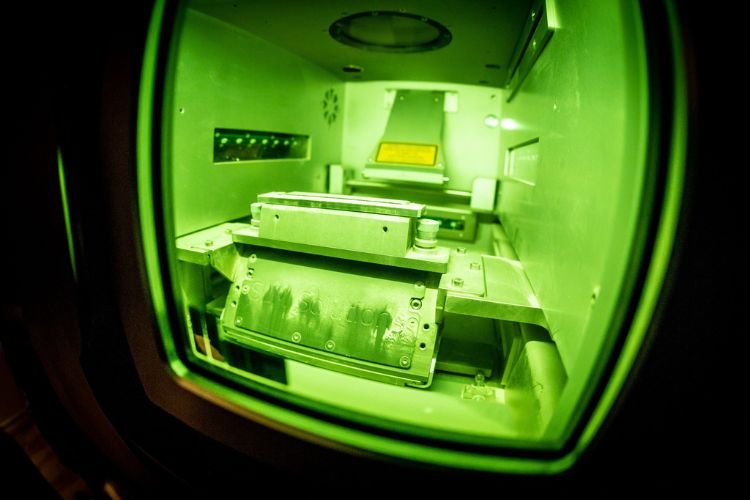

We at the moment solely work with 925 sterling silver. We now have a companion who buys scrap silver from everywhere in the world and refines it into silver powder which we use for direct steel 3D printing. We use a selective laser melting expertise to immediately 3D print jewellery gadgets from 100% recycled silver. Many have requested why we now have chosen this printing expertise. The reply is straightforward: it’s the most useful resource environment friendly, because it omits a lot of the sophisticated manufacturing steps which are important when utilizing conventional strategies. It permits us to automate all our manufacturing processes and finally save time, materials, human sources and the planet. It’s the expertise that most closely fits our grand imaginative and prescient of constructing a community of absolutely automated and sustainable jewellery printing facilities world wide, providing a singular, quick and carbon-free service to manufacturers, creators and people.

Cloud Manufacturing unit makes use of a steel 3D printer to fabricate silver jewellery gadgets

3DN: What benefits and limitations do you discover in steel 3D printing?

Know-how has numerous benefits amongst these talked about above. It permits us to supply tremendous quick and versatile manufacturing, customizations, restricted runs, new merchandise launches in solely days and helps us to completely automate this labor-intensive trade. The one limitation in the meanwhile is product improvement time on the subject of creating complicated 3D fashions. For extra detailed designs, it may well take a few days to complete the fashions to start out the sampling course of. That’s why we’re additionally engaged on improvement that may assist us automate the a part of product improvement that requires numerous handbook work: changing 2D designs into 3D. This could assist us onboard new clients sooner than ever earlier than.

3DN: How do you see the way forward for additive manufacturing within the jewellery trade?

I believe the method that Cloud Manufacturing unit makes use of will certainly be a key component of the trade inside a decade – relative to the elevated restrictions throughout the trade to cease polluting actions, conventional producers are in search of new methods to be extra planet pleasant and to satisfy the wishes and of the subsequent technology’s clients.

3DN: Any final phrases for our readers?

Cloud Manufacturing unit is pioneering the sustainable journey of advantageous jewellery. We all know that the jewellery trade is profitable, but it surely has been limiting its potential for hundreds of years because of the want for intensive manufacturing know-how, upfront funds and prolonged improvement processes. We’re right here to vary the sport: we wish to make the jewellery trade match to ask future generations into this and conventional but fashionable, enjoyable, reasonably priced and good for our planet. If you wish to know extra about Cloud Manufacturing unit you’ll be able to go to our web site HERE.

What do you consider Cloud Manufacturing unit? Tell us in a remark under or on our Linkedin, Fb, and Twitter pages! Don’t neglect to join our free weekly Publication right here, the most recent 3D printing information straight to your inbox! You can even discover all our movies on our YouTube channel.