Additive Assurance has agreed to combine its in-situ course of monitoring system into Additive Industries’ MetalFab laser powder mattress fusion (LPBF) 3D printers This collaboration seeks to enhance steel 3D printing course of monitoring in high-value purposes.

Because the construct charge and productiveness of steel 3D printers elevated, in-process monitoring and high quality assurance capabilities are rising in significance.

This know-how performs a vital position in making certain repeatability, attaining high-reduction yield, and mitigating the chance of wasted materials brought on by failed builds. As such, Additive Industries will now supply reside 3D printer monitoring capabilities to its buyer base.

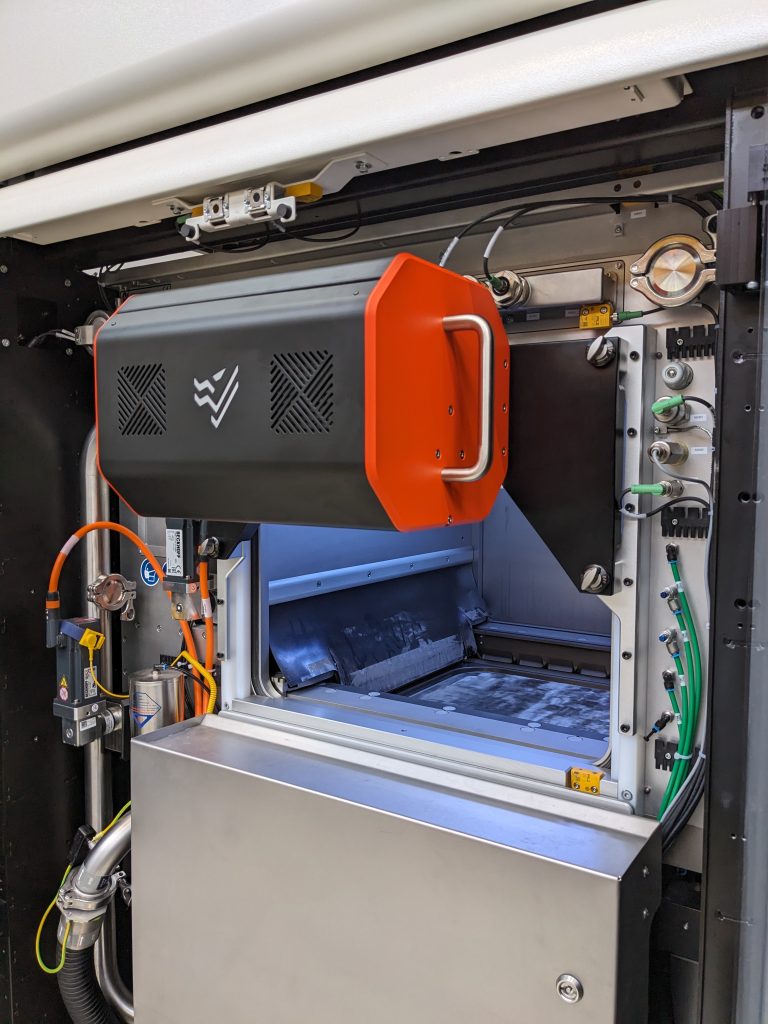

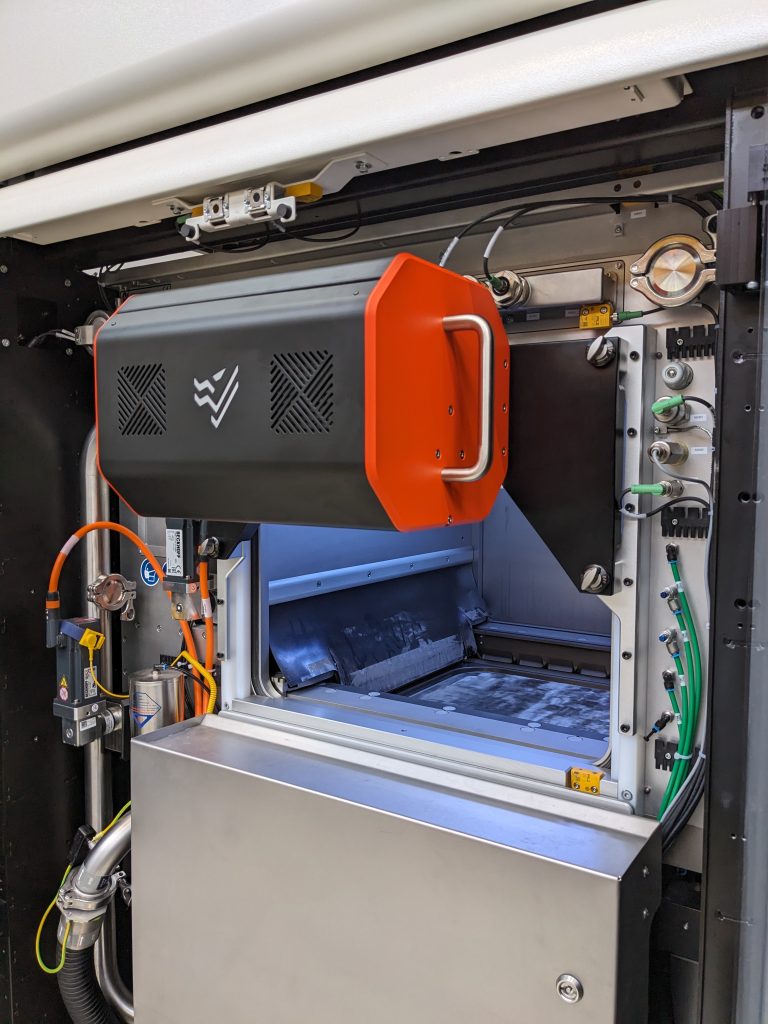

The corporate’s MetalFab 3D printers will combine Additive Assurance’s AMiRIS high quality inspection system. This unit, which could be mounted immediately onto MetalFab, gives reside insights into the 3D printing course of. This may reportedly strengthen certification and high quality assurance efforts, enabling shorter manufacturing cycles and higher confidence within the last product.

“Our partnership with Additive Assurance aligns completely with our dedication to advancing the capabilities of steel additive manufacturing,” commented Mark Massey, Additive Industries’s CEO.

“By integrating AMiRIS with our MetalFab portfolio, together with our new MetalFab 300 Flex, we’re enhancing real-time high quality assurance, providing our prospects higher flexibility, and setting new requirements in manufacturing consistency and reliability.”

MetalFab 3D printers combine in-situ monitoring

Since its founding in 2012, Additive Industries has constructed a considerable portfolio of commercial LPBF 3D printers. The corporate launched its first system, the MetalFAB1, again in 2016. The 3D printer has since been leveraged by prospects in aerospace, automotive, industrial, vitality, and high-tech market verticals.

Extra just lately, throughout RAPID + TCT 2024, Additive Industries unveiled its latest providing, the MetalFab 300 Flex. This distinctive system options an extendable construct plate that may be accessed by a month-to-month or lifetime license. Prospects can prolong the construct space from 11.81 x 11.81 x 15.75in to 16.54 x 16.54 x 15.75in at any time, to satisfy particular software wants.

Based on the 2 firms, AMiRIS is a logical extension to the MetalFab sequence of LPBF 3D printers. It can reportedly tackle key high quality assurance (QA) challenges confronted in industrial purposes comparable to house and aerospace manufacturing.

Based mostly in Melbourne, Australia, Additive Assurance launched the beta model of its steel 3D printing high quality assurance platform in 2019. The corporate launched as a spinout of a mission carried out by Monash College and Australia’s Defence Science and Expertise Group.

Its in-situ monitoring unit permits QA reporting throughout a fleet of a number of machine varieties. A patent-pending know-how, it makes use of optical sensors to collect micron-level element in the course of the 3D printing course of. Machine studying is employed to analyse this information, offering insights into the steel additive manufacturing course of.

AMiRIS is designed to detect numerous 3D printing course of instabilities. It options adjustable thresholds for monitoring, notification and intervention to make sure excessive 3D printer utilization and high quality management.

“We’re delighted to be working with Additive Industries so as to add worth to their buyer’s expertise and to push the boundaries of what’s attainable with L-PBF AM,” added Marten Jurg, CEO of Additive Assurance.

The partnership will see broader deployment of in-situ monitoring for MetalFab customers. This, the businesses declare, might result in higher adoption of LPBF 3D printing sooner or later.

Defect detection for steel 3D printing

Defect detection and high quality assurance have rapidly turn into important instruments for steel 3D printing purposes, as producers look to spice up productiveness, guarantee high quality, and scale back waste. This demand has seen extra firms develop and introduce new course of monitoring choices.

Earlier this yr, Chicago-based 3D printing high quality assurance software program developer Phase3D introduced a collaboration with the USA Air Pressure (USAF) and NASA to develop Fringe Analysis. This new in-situ monitoring software program is claimed to be the primary to measure anomalies throughout steel powder mattress fusion (PBF) 3D printing and correlate these to defects within the last half.

Based on Niall O’Dowd, Founder and CEO of Phase3D, the defect-detection software program will enhance 3D printer throughput by over 10% yearly. This shall be achieved by stopping the manufacturing of elements that might later fail inspection. Particularly, the software program is particularly effectively suited to detecting porosity in 3D printed elements. This can be a pertinent problem for aerospace purposes. Porosity usually causes steel elements to be rejected by the USAF and NASA.

Elsewhere, 3D printing software program and companies firm Materialise affords its AI-powered Course of Management software program for steel 3D printing. Via this software, customers can analyze information collected throughout 3D printing to regulate the standard of their elements.

This enables faulty elements to be positioned earlier than the post-processing and high quality inspection phases, saving customers money and time. Based on Materialise, these steps can add 30% to 70% to the prices of a last half.

Need to assist choose the winners of the 2024 3D Printing Business Awards? Be part of the Skilled Committee right this moment.

What does the way forward for 3D printing maintain?

What near-term 3D printing tendencies have been highlighted by trade specialists?

Subscribe to the 3D Printing Business publication to maintain updated with the most recent 3D printing information.

You may also comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture reveals an AMiRIS unit mounted on a MetalFAB G2 3D printer. Picture through Additive Assurance.