On this version of Sliced, the 3D Printing Trade information digest, we cowl the newest enterprise developments, partnerships, and acquisitions within the additive manufacturing sector.

At present’s version options new supplies, partnerships, and enterprise offers, and SPEE3D and ASTRO America securing awards.

Learn on for the latest updates from Sintratec, Xact Steel, Marketiger, RICOH 3D for Healthcare, and extra.

New supplies from Uniformity Labs, AddUp, 6K Additive, and extra

Diving into new supplies, AddUp joins a $1.5M analysis contract with the US Air Power (USAF) and Small Enterprise Innovation Analysis (SBIR) program, led by REM Floor Engineering (REM). The contract is titled “Improvement of Manufacturing, Warmth Therapy, and Floor Ending Pointers to Yield Prepared-to-Use IN-718 Additive Manufacturing Elements.” The venture focuses on leveraging laser powder mattress fusion (LPBF) and floor ending applied sciences to supply IN-718 elements for armament methods. It investigates the influence of warmth remedy, printing parameters, and REM’s floor ending on mechanical properties. AddUp and Zeda assist the venture, aiming to supply manufacturing pointers for LPBF to satisfy USAF’s readiness objectives.

Subsequent up, engineered supplies firm Uniformity Labs has launched UniJet SS17-4PH Efficiency, an ultra-low porosity 17-4PH chrome steel powder, for the Desktop Steel Manufacturing System. The corporate goals to supply uncompromised metallic additive manufacturing (AM) options to the {industry}. The qualification course of on Desktop Steel’s Manufacturing System concerned intensive analysis of the bodily and mechanical properties of UniJet 17-4PH powder, yielding distinctive outcomes. UniJet 17-4PH displays superior uniform powder mattress layering, leading to twice the inexperienced energy and a mean of 20% much less shrinkage in comparison with different stainless-steel powders authorised to be used with Desktop Steel’s Manufacturing System. These qualities, mixed with industry-leading powder mattress uniformity, contribute to improved geometric accuracy of sintered components and decreased breakage throughout post-print dealing with and depowdering. Consequently, the method yields high-quality components with elevated throughput.

6K Additive lately declared that its environmentally pleasant tungsten powder has efficiently met the necessities for processing by Wayland Additive’s NeuBeam print course of. This achievement opens up prospects for creating elements within the nuclear, aerospace, and hypersonic sectors. With this qualification, it turns into possible to make the most of the challenging-to-process tungsten powder in additive manufacturing, enabling the manufacturing of components for novel nuclear purposes, hypersonic applied sciences, and different aerospace tasks that demand high-level warmth resistance.

Moreover, Kimya has launched the Kimya ABS-R 3D filament, a brand new normal ABS filament composed completely of post-consumer recycled materials. Kimya believes this novel filament promotes the development of a round financial system by minimizing CO2 emissions, lowering water and electrical energy consumption, and lessening reliance on oil sources throughout manufacturing. Acrylonitrile butadiene styrene (ABS) is a thermoplastic polymer identified for its light-weight nature, superior influence resistance, and dependable temperature sturdiness. ABS is usually employed in purposeful prototyping and enclosure purposes throughout varied industries, together with home equipment, telecommunications, and extra.

Rising partnership information from Sintratec, B9Creations, SLM Options, Tekna, and extra

Now continuing with partnerships, Swiss producer of 3D printers Sintratec has shaped a partnership with Solar Digital to introduce its 3D printing applied sciences in Mexico. With over 50 years of expertise, the Mexico Metropolis-based firm focuses on promoting and servicing label packaging, and shade 3D printers. Because the unique companion of HP Indigo Digital Presses out there, Solar Digital has lately launched an Additive Division, “marking its foray” into the 3D printing sector. This collaboration with Sintratec is a major step for each corporations, because it permits Sintratec to determine a foothold within the Mexican market and increase its gross sales and repair community in North America.

Sintratec is strengthening its distribution and repair community in Jap Europe by collaborating with Croatian firm 3DPrintaj. This partnership marks a major milestone as 3DPrintaj turns into the primary consultant of Sintratec’s SLS (Selective Laser Sintering) methods in Croatia. 3DPrintaj is increasing its vary of choices by incorporating SLS know-how into its product portfolio. This enlargement enhances its current lineup of FDM and DLP machines from respected suppliers like Phrozen, Raise3D, and Zortrax. To perform this, 3DPrintaj is using the Sintratec All-Materials Platform (AMP), which boosts manufacturing capabilities. This collaboration allows 3DPrintaj to cater to a wider vary of buyer calls for sooner or later. For Sintratec, this partnership represents a major stride into the Jap European market, marking its debut in nations equivalent to Croatia, Bosnia and Herzegovina, and Slovenia.

Additive manufacturing providers supplier B9Creations has joined forces with a analysis workforce from South Dakota Mines. Their collaboration goals to research the basis causes of osteoarthritis and lay the groundwork for potential future discoveries that would result in a remedy for this long-standing illness that has challenged scientists for a few years.

The analysis workforce from South Dakota Mines has made vital developments within the area of osteoarthritis by using B9Creations’ 3D printing know-how. By their efforts, they’ve efficiently developed and patented a novel know-how referred to as CellWell. Moreover, they’ve established a startup firm to additional discover its potential. CellWell, along with a 3D printed housing that connects it to different joint elements equivalent to bone and synovial membrane fashions, permits for the examination of cartilage cells in a fashion that carefully resembles their pure state. This mixture of instruments supplies researchers with unprecedented alternatives to look at and take a look at cartilage cells, resulting in invaluable insights into the underlying causes of osteoarthritis that had been beforehand unattainable, says B9Creations.

Industrial metallic 3D printer producer AddUp has lately grow to be a member of the Dassault Systèmes 3DEXPERIENCE platform ecosystem. Dassault Systèmes provides a complete suite of purposes throughout the 3DEXPERIENCE platform particularly designed for additive manufacturing. These purposes embody varied elements equivalent to materials characterization, personalized design, preparation and simulation of construct jobs, in addition to scheduling and monitoring of shopfloor actions. By using this built-in platform, customers can guarantee seamless digital continuity all through your complete lifecycle of components manufacturing. AddUp has developed the Digital Twin of the FormUp 350, using its devoted interoperability answer known as AddUp NTwin, which permits for seamless integration with the 3DEXPERIENCE platform. AddUp NTwin allows customers of the 3DEXPERIENCE platform to effortlessly generate job information, entry extra construct data, and conduct simulations. Hosted by Dassault Systèmes It’s accessible to customers throughout the AddUp group.

AMEXCI AB, a Swedish accelerator for adoption of 3D printing applied sciences has partnered with AMPOWER, an AM consultancy, to announce their upcoming on-line coaching programs. The goal of those programs is to help each their members and prospects in studying and implementing additive manufacturing at a sooner tempo.

This complete coaching program contains 5 programs tailor-made for people who’re new to additive manufacturing, in addition to these with intermediate information within the area. The AMPOWER Academy platform was unveiled at Formnext 2022 as a web based instructional useful resource, designed to expedite self-paced studying for engineers, purchasers, and high quality managers. The platform covers important topics associated to additive manufacturing, together with know-how fundamentals, operational rules, frequent purposes, and prevailing market developments. This permits each particular person workers and whole organizations to entry the net platform and purchase information at their very own comfort.

Steel 3D printer producer SLM Options has introduced a collaboration with the Danish Technological Institute (DTI) to scale up additive manufacturing industrialization. This collaboration goals to rework metallic additive manufacturing by establishing superior parameters for SLM machines, significantly the NXG XII 600. DTI is growing sooner course of parameters for chrome steel 316L and copper alloy CuCr1Zr utilizing their SLM 280 2.0. The main target is on cost-effective manufacturing, leveraging SLM Options’ open structure method. The partnership will discover materials growth for superior elements with crucial electrical and thermal conductivity necessities. It additionally allows quick manufacturing of sturdy chrome steel elements.

Tekna has introduced its collaboration with TriTech Titanium Elements, a Detroit-based additive manufacturing firm to create a novel titanium powder that meets aerospace AS9100 and medical ISO 13485 requirements. This high-quality powder is particularly designed to make sure excellent half high quality and mechanical properties. By leveraging Tekna’s industrial-grade titanium powder, TriTech is ready to absolutely make the most of binder jet 3D printing know-how, enabling the manufacturing of personalized, light-weight, and robust titanium components that surpass the constraints of typical manufacturing strategies.

6K Additive, has introduced an settlement with Australia-based Surgical Steel Recycling (SMR). This partnership goals to rework the metals provide chain in Australia. One space of focus is advancing the remedy course of for surgical implants which have reached the tip of their lifespan. Underneath the settlement, SMR will present used and out-of-spec implants, swarf, and used metallic additive manufacturing powder. This materials will probably be reprocessed using 6K Additive’s UniMelt production-scale microwave plasma platform. Initially, the reprocessing will happen within the U.S., with plans to increase to Europe sooner or later. The result of this course of would be the creation of premium powders that may be utilized for additive manufacturing to supply new components. The final word purpose of the partnership is to determine a sustainable and round provide chain, enabling the creation of licensed implants from current components.

AMAZEMET and AXT have shaped a strategic partnership, marking AMAZEMET’s introduction into the Australian market. In doing so, AXT will increase its choices and unlock new enterprise prospects by incorporating AMAZEMET’s merchandise. The partnership entails the distribution of AMAZEMET’s product vary, which incorporates the rePowder ultrasonic atomizer for metallic powder manufacturing, the inFurner excessive vacuum furnace, and the safeEtch gadget for automated removing of fixtures from 3D printed metallic elements. By this collaboration, AXT can present its prospects with entry to novel applied sciences for the additive manufacturing of metallic components.

Powder mattress fusion (PBF) 3D printers supplier EOS has introduced that it will likely be additional strengthening Indiana Tech‘s STEM program. By this partnership, EOS will provide the college with two extremely superior 3D printers: the FORMIGA P 110 Velocis and the EOS M 290. Indiana Tech’s Talwar Faculty of Engineering and Laptop Sciences is ready to boost its additive manufacturing capabilities by the addition of two superior 3D printers. The FORMIGA P 110 Velocis, a polymer SLS printer, provides excessive precision and backbone, making it appropriate for prototyping, tooling, and remaining half manufacturing throughout varied purposes. Then again, the EOS M 290, a metallic DMLS printer, creates high-performance metallic elements. These printers will play a significant position in offering college students with sensible expertise in additive manufacturing. Furthermore, they are going to assist the college’s biomedical and superior manufacturing applications.

British multinational producer GKN Aerospace and Materialise, a 3D printing service supplier have agreed to collaborate by a Letter of Intent (LOI). Their joint efforts give attention to enhancing the analysis, design, and manufacturing of polymer 3D printed elements for the aviation sector. The partnership goals to expedite the certification course of for additive manufacturing and discover new prospects for producing purposeful and flight-critical aerostructures, benefiting from the distinctive advantages provided by this manufacturing methodology.

“This highly effective alliance goals to leverage our mixed experience and the distinctive advantages of 3D printing to push the boundaries of innovation within the aeronautics {industry},” mentioned Jurgen Laudus, Vice President of Materialise Manufacturing. “Collectively, we goal to drive technological developments, reply extra successfully to buyer necessities, and form the way forward for aerospace manufacturing.”

Industrial 3D printer producer Roboze and Magnaghi Aeronautica signed an MOU on the Paris Air Present 2023. The main target is on weight and emissions discount, and certifying the manufacturing course of utilizing Roboze 3D printing. Beforehand, polymer 3D printing was restricted to aerospace interiors. Roboze and Magnaghi goal to supply class 2 and three touchdown gear elements, standardizing manufacturing and qualification for 3D printing.

Enterprise and acquisition offers from Xact Steel, Nexa3D, Paul Horn, and extra

Steel 3D printer producer Xact Steel has reached a major milestone by receiving its one centesimal printer order. This achievement follows the profitable launch of the XM200G, its second metallic 3D printer, in 2021, increasing its buyer base.

“Our success in reaching this milestone is a testomony to the laborious work and dedication by the Xact Steel workforce and our international community of gross sales companions, who share our ardour for increasing entry to this know-how whereas offering the very best expertise for our prospects,” mentioned Juan Mario Gomez, CEO of Xact Steel. “We’ve been in a position to notice our unique speculation, which was that metallic 3D printing has a major place in the way forward for manufacturing for small-to-medium-sized corporations when there may be an avenue for elevated adoption. By designing Xact Steel merchandise for ease of use, accessibility, and affordability, we have now offered the chance for adoption to over 100 prospects and counting.”

RE3DTech, Stanfordville Machine & Manufacturing, Phoenix Proto Applied sciences, and GoProto, have joined forces to kind UPTIVE. This merger brings collectively their experience in additive manufacturing, CNC machining, sheet metallic fabrication, speedy prototyping, post-processing and ending, injection molding and tooling. UPTIVE’s devoted workforce supplies personalised steerage and exact growth of customized components, turning their “shoppers’ visions into actuality.” The corporate has unveiled its new branding and improved on-line presence at uptivemfg.com, the place prospects can entry many sources, together with quote requests and a information base library.

Carbide device producer Paul Horn has adopted the Solukon SFM-AT350, developed by Solukon Maschinenbau GmbH, to automate the depowdering course of for its device elements manufactured utilizing selective laser melting. The Solukon SFM-AT350 is a totally automated depowdering system that makes use of rotation, vibration, and compressed air to successfully take away residual powder from intricate metallic components. Particularly designed for medium-sized components weighing as much as 60 kg, the system will be utilized to depowder a variety of supplies equivalent to chrome steel, titanium, device metal, and aluminum.

“The Solukon system will increase security (explosion safety) as a result of we are able to additionally use it to depowder metallic components made from reactive supplies in a protecting gasoline environment,” mentioned Bartkowiak. Bartkowiak and his workforce additionally depend on the Solukon system for its contribution to sustainability.

Subsequent up, high-speed resin 3D printer producer Nexa3D has accomplished the acquisition of Addifab, an organization specializing in freeform injection molding. This strategic transfer enhances Nexa3D’s additive manufacturing capabilities, enabling it to realize sooner and extra environment friendly manufacturing of high-performance components.

“We’re very excited to welcome your complete Addifab workforce to the rising Nexa3D household of individuals, merchandise and companions democratizing entry to dissolvable tooling for identical day complicated molded components with a whole bunch of commercial plastics,” mentioned, Avi Reichental, Co-Founder, Chairman and CEO of Nexa3D.

3D printer OEM Stratasys has efficiently finalized the acquisition of Covestro AG‘s additive manufacturing supplies enterprise. The acquisition is predicted to have an instantaneous constructive influence, incorporating R&D services, international gross sales groups, and intensive mental property property. Stratasys has gained roughly 60 AM supplies and a major IP portfolio comprising quite a few patents and pending patents. These new sources and skills will allow Stratasys to discover novel purposes in crucial know-how sectors like stereolithography, P3/DLP, powder mattress fusion, and SAF know-how. Furthermore, they are going to complement Stratasys’ current experience in PolyJet and FDM applied sciences, strengthening the corporate’s supplies capabilities.

Side Biosystems and Novo Nordisk have unveiled a collaboration price $2.6 billion to collectively work on the development of bioprinted tissue therapeutics particularly aimed toward addressing diabetes and weight problems.

Underneath the settlement, Side will obtain an preliminary fee of US$75 million, in addition to potential funds of as much as US$650 million per product for a most of 4 merchandise. This brings the overall worth of the deal to over US$2.6 billion, along with tiered royalties primarily based on product gross sales. This collaboration will leverage Side’s proprietary bioprinting know-how alongside Novo Nordisk’s experience in stem cell differentiation, together with their capabilities in cell remedy growth and manufacturing. The first focus would be the growth of bioprinted tissue therapeutics that may successfully regulate blood glucose ranges with out the requirement for immunosuppression. This novel method holds the potential to revolutionize remedy choices for people residing with sort 1 diabetes globally.

Additive manufacturing service supplier ADDMAN has introduced its participation within the Roboze 3D Elements Community at Fast+TCT 2023. This strategic transfer goals to boost ADDMAN’s industrial manufacturing capabilities by incorporating additive manufacturing methods into their operations.

“We’re happy to grow to be part of the Roboze 3D Elements Community,” says Joe Calmese, CEO of ADDMAN. “We discovered a companion in Roboze who shares our imaginative and prescient for the current and future of producing – using know-how and innovation to handle the challenges we face. The shift in the direction of digital manufacturing is turning into more and more vital in mild of adjusting market calls for and environmental considerations, and we consider that Roboze may help us obtain one of the best for our prospects.”

The US Navy has chosen SPEE3D‘s metallic chilly spray additive manufacturing (CSAM) know-how for a venture led by Naval Sea Techniques Command (NAVSEA) targeted on Expeditionary Upkeep and Sustainment. The target of the venture is to develop supplies that meet the high-quality requirements of the Submarine Security Program (SUBSAFE).

The Utilized Analysis Laboratory of the Pennsylvania State College (ARL/PSU), a trusted companion of NAVSEA in chilly spray know-how, has subcontracted SPEE3D for the venture. This collaboration represents the primary exploration of chilly spray additive manufacturing as a possible methodology for producing SUBSAFE-compliant elements. Working alongside the US Navy and ARL/PSU, SPEE3D goals to develop a novel method for the speedy manufacturing of important submarine system components utilizing its know-how.

Multi-material 3D printer developer Inkbit has introduced the supply of its 3D printing providers. Producers who require intricate geometries and multi-material components for his or her polymer merchandise now have the choice to acquire prototypes and manufacturing volumes with out investing in an Inkbit Vista System.

Inkbit’s know-how permits for native multi-material printing, enabling the creation of complicated buildings with built-in delicate gaskets. The Inkbit course of incorporates real-time 3D inspection, guaranteeing distinctive accuracy and constant precision throughout all elements on the print mattress. Consequently, these elements match collectively seamlessly throughout meeting. With Inkbit’s superior know-how and dedication to meticulousness, prospects can have full confidence within the constant supply of exact and high-quality outcomes.

US 3D printer producer nano3Dprint has revealed a strategic distribution partnership to increase the supply and accessibility of nano3Dprint’s 3D printing applied sciences within the Japanese market. Japanese agency System Create, will function the distributor for nano3Dprint’s A2200 3D Multi-material Electronics 3D Printer and B3300 Twin-Shelling out 3D Printer, catering to prospects throughout Japan.

“The amount of 3D printer gross sales is increasing considerably. The driving components are shorter product growth instances, value financial savings and robust pushes for automation,” mentioned Renato Sugiyama, World Gross sales Assistant, at System Create Co.

Austrian ceramic 3D printing firm Lithoz has delivered a CeraFab S65 System 3D printer to WZR ceramic options GmbH, a cloth growth service supplier in ceramic 3D printing. A Rheinbach-based firm is utilizing high-precision Lithography-based Ceramic Manufacturing (LCM) know-how to create complicated cerium oxide elements for the “Redox3D” venture. This initiative goals to generate inexperienced hydrogen independently from fossil fuels in photo voltaic tower energy vegetation. By using 3D printed ceramics and harnessing daylight, this solar-thermochemical course of is a key answer for attaining zero-emission societies.

Quick-growing manufacturing and prototyping producer, Rennscot MFG, has acquired the EOS M 300-4, a high-productivity direct metallic laser solidification (DMLS) 3D printer. This addition strengthens Rennscot MFG’s complete manufacturing capabilities, which embody design, product growth, prototyping, and manufacturing utilizing each conventional and 3D printing strategies. Because of this partnership, EOS has welcomed Rennscot MFG as the newest member of its Service Supplier community.

“After visiting EOS’ services in Germany, it was clear that an EOS machine was the best selection for us,” mentioned David Bamforth, Rennscot MFG president and CEO. “This know-how permits us to create sophisticated components that couldn’t be produced utilizing conventional manufacturing strategies. To not point out, this know-how permits our prospects to have a single supply for extremely complicated additive components that will additionally require post-machining.”

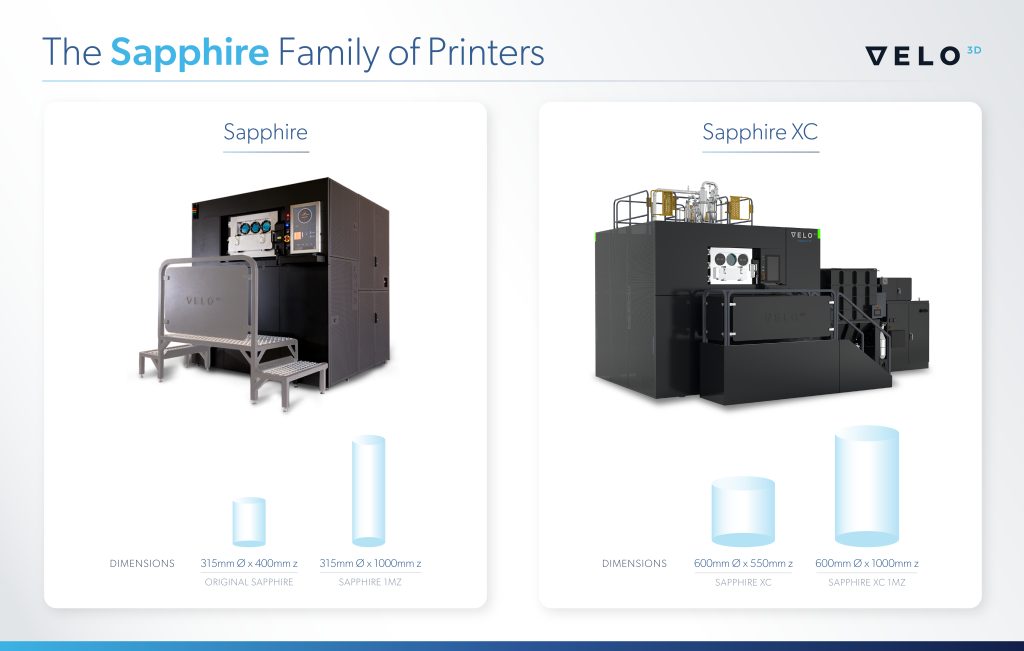

Steel 3D printer producer Velo3D lately introduced that Avio S.p.A., an aerospace firm listed on the Italian Inventory Change, has acquired a Sapphire XC 1MZ 3D printer and an unique Sapphire 3D printer. These additions will help within the growth and manufacturing of Avio’s propulsion methods, whereas additionally contributing to the progress of the area {industry}. Velo3D’s answer was chosen for its capability to fabricate high-quality components with optimized geometries, guaranteeing superior efficiency. The Sapphire XC 1MZ 3D printer provides a major benefit with its giant construct quantity. Each printers are calibrated to supply components utilizing a nickel-based alloy identified for its energy and resistance to corrosion, even underneath excessive temperatures.

“Avio is among the main area corporations in Europe and we’re thrilled to companion with them of their pursuit of groundbreaking propulsion methods,” mentioned Benny Buller, Founder and CEO of Velo3D. “They work with among the most modern corporations and companies in Europe and world wide to supply them with the know-how they should attain area. The Sapphire XC 1MZ will assist Avio additional speed up the event of its propulsion methods and contribute to the continued transformation of the area {industry}.”

RICOH 3D for Healthcare receives FDA 510k certification

RICOH 3D for Healthcare has obtained FDA 510(okay) clearance from the U.S. Meals and Drug Administration for increasing its diagnostic purposes. These embody patient-specific anatomic modeling in varied areas equivalent to genitourinary, neurological, cardiovascular, gastrointestinal, and breast purposes.

“Receiving the expanded 510(okay) clearance for anatomic modeling of sentimental tissue is an thrilling milestone for Ricoh as we proceed to paved the way in providing democratized entry to patient-specific 3D-printed fashions in healthcare,” mentioned Gary Turner, managing director, Additive Manufacturing, North America, Ricoh USA, Inc. “As a producer of precision additive medical gadgets, Ricoh provides one of many broadest scopes of FDA-cleared 3D fashions for anatomic areas and a variety of print supplies out there for diagnostic use – which mix to enhance outcomes, improve the affected person expertise and improve alternatives for doctor training and coaching.”

Novel software program from Marketiger and Creaform

3D printing options supplier Marketiger is helping prospects in simplifying and lowering prices related to mass customization purposes. By leveraging its design proficiency and a novel built-in answer combining software program and manufacturing, Marketiger allows this transformation. Its customization software program facilitates a seamless workflow encompassing asset importing, 3D printing, transport, and billing. This software-integrated manufacturing mannequin provides manufacturers an environment friendly means to generate extra income streams and improve buyer interplay utilizing their current or potential 3D property.

Creaform, a unit of AMETEK, Inc., has launched VXelements 11, an anticipated improve with new options and improved efficiency. The key change is seen in VXelements’ dimensional inspection module, VXinspect, which is now break up into two modules: VXinspect|Evaluation and VXinspect|High quality Management. Each modules are optimized for various phases of producing high quality management. VXinspect|Evaluation is a user-friendly software program for streamlined dimensional root trigger analyses, whereas VXinspect|High quality Management is a complete 3D inspection software program for superior high quality management in manufacturing.

Insights obtained from additive manufacturing-related analysis

In keeping with a latest investigation performed by the Chemical Insights Analysis Institute (CIRI), it has been found that 3D printing can emit varied dangerous pollution into the environment. These pollution embody unstable natural compounds (VOCs), ultrafine particles, and metallic aerosols. Publicity to those pollution can result in a number of well being points equivalent to respiratory irritation, bronchial asthma, most cancers, and reproductive problems.

The research was carried out inside a college maker heart and revealed that the degrees of VOCs in rooms the place 3D printers had been operational had been as much as 100 instances larger in comparison with different areas. Moreover, the research noticed considerably elevated ranges of particles, some as small as 0.1 micrometers in diameter. These minuscule particles have the flexibility to be inhaled deeply into the lungs, thereby posing extreme well being dangers.

Binder jetting is an additive manufacturing methodology gaining reputation as a consequence of its cost-effectiveness and materials selection. Nonetheless, it’s slower than conventional strategies. A research suggests an answer: adaptive slicing. By adjusting layer thickness primarily based on complexity, printing time will be decreased with out compromising high quality. Researchers from Ondokuz Mayıs College used adaptive slicing to print samples, leading to 38% fewer layers and vital time financial savings with out high quality loss. In addition they developed a binder algorithm to enhance half high quality. Adaptive slicing exhibits promise for dashing up binder jetting, with potential for additional developments.

Researchers from KU Leuven, Thomas Extra College, the Belgian Welding Institute npo, and Sirris have made developments in enhancing the standard of additively manufactured components. Their analysis carried out underneath the “Advert-Proc-Add venture,” targeted on the additive-subtractive manufacturing course of chain (ASM). Notably, the venture revealed that the parameters of the WAAM course of play a major position in figuring out efficient wall width, floor high quality post-deposition, and the quantity of fabric removing required throughout post-processing. To additional examine the influence of various processes on remaining half properties, the researchers developed multi-sensor platforms. These platforms enabled monitoring of present, voltage, gasoline circulation fee, and temperature, facilitating the analysis of WAAM course of stability. This method proved efficient in mitigating materials defects and enhancing floor efficiency.

3D printing purposes information

Shifting ahead with novel purposes, Ada Hefetz, a preferred marriage ceremony gown designer primarily based in Israel, has launched a fascinating assortment utilizing Stratasys’ direct-to-textile 3D printing know-how. Showcased at Milan Design Week, the three attire are impressed by Hefetz’s Flower of Life theme. Created with Stratasys’ 3DFashion know-how, they have a good time the matrimonial union and the circle of life. The attire characteristic intricate geometrical shapes representing the Flower of Life, mixed with Hefetz’s lily design. Stratasys’ J850 TechStyle 3D printer, utilizing translucent VeroVivid resin, supplies over 500,000 distinctive colours and ranging flexibility for various textures and finishes.

Excessive Productiveness Wire Arc Additive Manufacturing (HPWAAM) group, has introduced it has efficiently demonstrated vital advances in technical functionality which is able to allow additive manufacturing to play a larger position in the way forward for the {industry}. They goal to industrialize HPWAAM with thermal management and variable decision for large-scale engineering elements. Supported by £1.2 million in funding from Innovate UK, the venture entails seven specialised organizations and is scheduled for completion by 2023. The collaboration builds on Cranfield College‘s analysis, exploring industrial alternatives and addressing sustainability considerations. Finish customers will develop up to date Designs for Additive Manufacturing frameworks to rework current elements.

Aniwaa broadcasts technological developments

Aniwaa, a web based market for AM and 3D seize options, has unveiled its first AM {hardware} panorama infographic.

This visible illustration showcases over 500 energetic AM {hardware} producers, categorized by supplies, know-how, and different components. In keeping with the corporate, the infographic reveals that polymer 3D printers are dominant, accounting for a considerable 57% of AM {hardware} producers. Steel 3D printers declare the second spot with a 27% illustration. The remaining 16% encompasses a various vary of AM applied sciences, together with ceramics, composites, and bioprinting. Notably, the infographic highlights the growing reputation of PBF know-how, which is now provided by 35% of producers, reflecting a rise from 25% in 2022. Fused deposition modeling (FDM) emerges because the second hottest AM know-how, with 28% of producers offering it.

Zortrax introduces metallic 3D printing choice

Zortrax is introducing a metallic 3D printing choice for its desktop M300 Twin 3D printer. This industrial-grade machine helps single- and dual-extrusion modes and is suitable with a variety of supplies, together with fundamental filaments, versatile supplies, Nylon, and strengthened polymers. To reinforce its capabilities, Zortrax provides two kits: Full Steel Package deal 316L and Full Steel Package deal 17-4 PH. These kits embody BASF Ahead AM’s metal-polymer filaments, equivalent to Ultrafuse 316L and Ultrafuse 17-4.

“Zortrax M300 Twin is a really common machine, which mixes a big workspace, single- and dual-extrusion modes, intuitive interface, and a really big selection of ready-to-use, calibrated materials profiles. We’re now including an choice of metallic 3D printing to this desktop printer with two complete units: Zortrax Full Steel Package deal 316L and Zortrax Full Steel Package deal 17-4 PH, encompassing the whole lot that’s crucial to begin metallic 3D printing and to make sure absolutely purposeful metallic components, which exhibit the properties of metal,” says Michał Siemaszko, Head of Analysis and Improvement Division at Zortrax.

Awards information from SPEE3D and ASTRO America

SPEE3D has been awarded as a winner within the Workplace of the Secretary of Protection Manufacturing Expertise (OSD ManTech) “Level of Want Problem.” The problem goals to search out options that may help deployed forces in difficult environments. This system will obtain an funding of roughly $2.5 million, with extra value sharing of $700,000 from {industry} companions.

“Given our confirmed observe file of working with the army in extremely popular and dry environments, we sit up for demonstrating our expeditionary manufacturing and restore capabilities in sub-freezing circumstances,” mentioned Byron Kennedy, CEO of SPEE3D. “We’re honored to work with the OSD to showcase our patented Chilly Spray Additive Manufacturing know-how.”

ASTRO America has been awarded a $1 million grant from the U.S. Nationwide Science Basis‘s Regional Innovation Engines program. ASTRO America is considered one of over 40 groups to obtain the inaugural NSF Engines Improvement Awards. The grant goals to advertise collaboration and create alternatives in financial, societal, and technological sectors. ASTRO America’s initiative, titled “Advancing Additive Manufacturing Applied sciences,” focuses on accelerating the adoption of 3D printing in provide chains and enhancing capabilities within the aerospace, protection, and power industries. The venture features a partnership with main firms and main minority-serving establishments to assist small and medium-sized suppliers in transitioning to additive manufacturing.

Replique closes seed funding spherical

Replique has lately grow to be an impartial entity after separating from Chemovator, the enterprise incubator of BASF. To assist its development, Replique has efficiently concluded a late seed funding spherical. The funding was led by digital know-how investor STS Ventures. Replique’s core providing is a safe 3D printing platform that allows sustainable spare half administration and small-scale manufacturing.

“We see a whole lot of startups with promising concepts, however Replique stood out to us as a game-changer within the manufacturing {industry}. Their modern industrial 3D printing platform has the potential to disrupt the {industry} and we’re excited to assist their development and enlargement sooner or later. Apart from the best answer, Replique additionally brings the best mindset and a very good workforce to the desk,” says Oliver Kaul, companion at STS Ventures.

UltiMaker broadcasts distribution deal

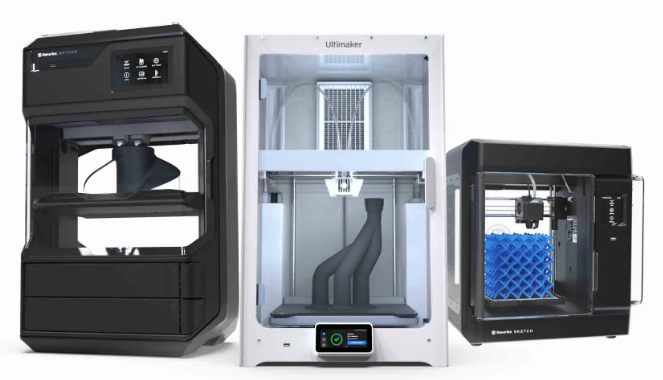

Desktop 3D printer producer UltiMaker has introduced the addition of the brand new UltiMaker Technique and Sketch product traces to its community. This enlargement is a major milestone for UltiMaker because it nears its 10-year anniversary because the unique distributor. The UltiMaker Technique collection combines industrial-grade capabilities with desktop comfort for distinctive high quality. The Sketch collection caters to the training market with user-friendly 3D printing options for creativity and prototyping.

“We’re extremely proud and excited to increase our distribution portfolio to incorporate the UltiMaker Technique and Sketch product traces,” mentioned Paul Croft, Director of UltiMaker GB. “As we method our 10-year anniversary, this vital milestone displays our dedication to providing one of the best 3D printing options to our prospects. We’re grateful for the assist of our reseller community, which has been instrumental in our success up to now.”

What does the way forward for 3D printing for the subsequent ten years maintain?

What engineering challenges will must be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you on the lookout for a job within the additive manufacturing {industry}? Go to 3D Printing Jobs for a collection of roles within the {industry}.