Computer-aided design (CAD) is an integral part of the digital workflow for additive manufacturing. This software is used to create, modify and analyze designs before they can be printed. Once the CAD file has been created, it can be used to slicing the file and then sent directly to the printer. This article will be about CAD. It is a high quality CAD/CAM software that allows you to create top-quality products for prototyping as well as for use in the final product. Creo is an example of such software. Creo, a 3D CAD solution, is part of PTC. This digital software company also offers CAD solutions. Creo is used in discrete manufacturing, which is the production of unique items.

What is the process?

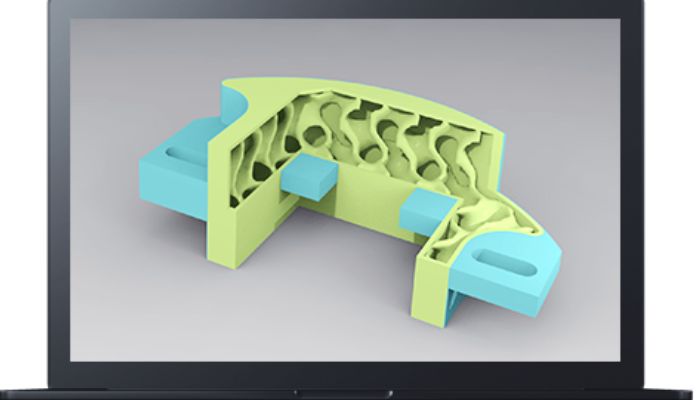

Creo can run on Microsoft Office. It is useful for additive manufacturing because it can speed up product innovation for complex designs. Combine advanced technologies such as generative designs and real-time simulating with traditional CAD software. Creo makes it possible to design, optimize and run a print test in one environment. This reduces the chance of errors. You can reduce the weight of your products by using Lattices. Products can also be printed in metal or polymer. See how the latest software works here:

Technical details of the latest release

Creo’s first edition was released in January 2011. Creo 9.0 was released in May 2022. This new version is known for its customer-driven useability and productivity enhancements that can make life easier. The digital product definition tool helps to improve model-based designs. It uses semantic PMI symbols and symbols that are compliant to international standards to prevent confusion. Creo 9 includes new weld symbols as well as drawing hatch patterns, which makes it easier for fine details to be produced. Overall, both downstream users and the user of the Creo 9 have high levels of clarity. Creo Flow Analysis and Creo Ansys Simulation have been improved for visualization. Creo Simulation Live allows users to run multi-physics analysis on the design to determine its performance and structure.

These features are crucial for additive manufacturing, as they allow the creation of detailed, high-quality designs that can be tested before printing. This allows for time and resource savings. According to Brian Thomson, divisional manager and general manager of Creo at PTC, the ninth edition “is an important release, and our customers’ feedback played a big part in making that happen”.

Creo can be purchased in various packages that are tailored to your needs. All packages start at $2780, and include 3D part assembly, design, management, performance, and more. Users can try the software for free for 30 days before making a purchase. PTC lists many industry-recognized uses of Creo software, from helicopter design to motorbikes. It has been used by KTM, Volvo and many other companies. Creo’s CAD software faces tough competition from the rest of the industry as other major players such as Solidworks offer a similar product, but Creo stands alone for its well-developed packages which offer simulation, augmented reality and more.

Creo design software. (Photo credit: PTC.com)

What do users think about Creo?

Creo 9.0 has been praised by users for its functionality and success. Creo 9.0 is also useful for large files, and offers useful features. Some users complained about a steep learning curve and limited automation due to fewer integrations. Users also feel that the UI is less intuitive than other softwares.

What do you think about Creo? Let us know in a comment below or on our LinkedIn, FacebookAnd Twitter pages! Don’t forget to sign up for our free weekly Subscribe to our Newsletter Receive the latest news on 3D printing directly to your inbox You can also view all of our videos at our YouTube channel.

*Cover photo credit: PTC