Other transformative technologies promise to change our lives as well. Artificial intelligence (AI), such as ChatGPT, will dominate headlines by 2023.

Don’t Miss: The Robot House-Printing is Shaking Up an Industry Worth $7.28 Trillion

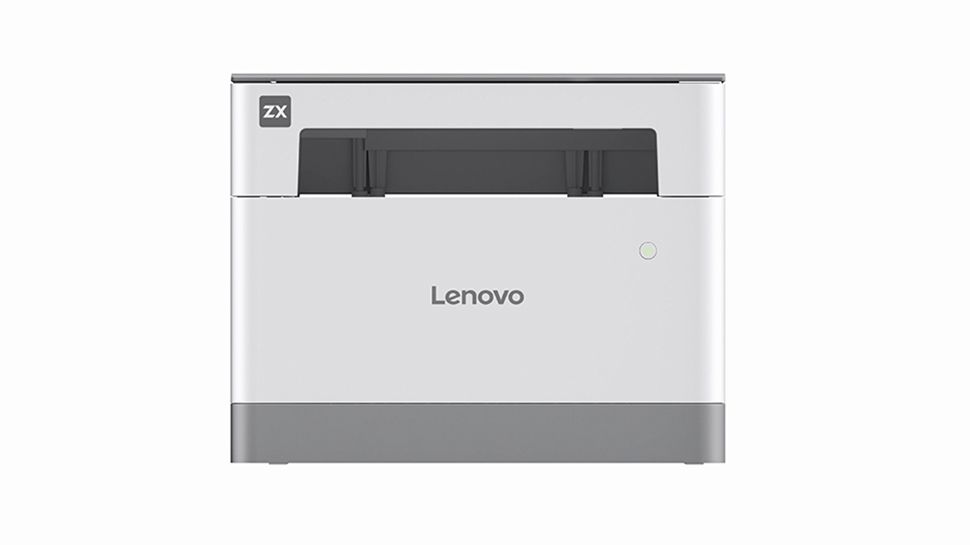

One of the most impactful innovations is 3D printers, machines that use computers — and can leverage AI — to build three-dimensional objects by layering together different materials.

According to a report from MarketsandMarkets™, the 3D printing market should grow to $34.5 billion by 2028, up from an estimated $15 billion in 2023. The technology will have an impact on every industry that relies on physical objects. The four most exciting areas include medical prosthetics and implants, construction, manufacturing of obsolete parts, and surgical implants.

Construction Speed Improvement

3D printing can be used for more than just small objects or trinkets. Some firms such as Apis Cor use the technology to build homes, and they’re making big money to do it.

The company uses 3D printed robots to pour customized concrete walls. With this technology a construction company can build a single-family home’s walls in about five working days, which compares to the five to eight weeks usually required for the project. The entire construction cycle can be shortened by several months. This allows firms to work more efficiently and meet deadlines. Apis Cor’s 3D printing capability helps construction firms increase output and manage skilled labor shortages that might otherwise slow production.

Apis Cor has a current crowdfunding on StartEngine. Anyone can invest in a limited period of time.

Designers have a new tool in 3D printing that allows them to create unique wall and home features using different shapes and textures. They can also experiment with blending different materials that can reduce a home’s carbon footprint and waste.

Customized Prosthetics

3D printers will make prosthetics more accessible to millions by removing barriers of cost. A 3D printer can create a custom prosthetic arm, leg or hand at a fraction the cost. They’re portable machines, can produce on-site prosthetics and offer low maintenance costs. The machines are also capable of creating new types of prosthetics, by offering athletes customized pieces that suit their needs within a sport.

3D printers, combined with AI, are enabling new features in prosthetics, such as synthetic skins that can simulate the sensation of touch, or lighter and more durable materials for future prosthetics.

Keep up with the latest news on startup investments and news. sign up for Benzinga’s Startup Investing & Equity Crowdfunding Newsletter

Saving Lives through Surgery

Medical 3D printers are used in a variety of ways. One is through custom 3D-printed surgical guides and instruments built for specific patients or to fit a surgeon’s hands. 3D printed models of organs, body parts and other body structures can be created by physicians using 3D scanner scans. This allows them to practice their surgical skills before they work on the real patient.

3D printing for surgical implants allows medical professionals to design and create customized implant that match the unique anatomy and needs of each patient. This leads to a higher rate of success and a lower risk of complications. In the future, hospitals will be able to create their own implants, with a variety of materials, depending on the patient’s needs, such as replacing a broken limb or assisting a hip surgery.

Don’t Miss: Qnetic Unveils Revolutionary Flywheel Energy Storage to Accelerate Renewable Energy Adoption

Keep Things on the Road, or in the Sky

The use of 3D printing prevents machinery and vehicles from falling into disrepair due to parts obsolescence. 3D-printed parts are increasingly being used by car enthusiasts for their classic cars, such as the 1967 Chevrolet Camaro and 1971 Ford Thunderbird. Car manufacturers are increasingly using 3D printing for testing, creating parts for concept vehicles and expanding production capacity.

The U.S. Armed Forces also use 3D printing in order to maintain equipment and vehicles, create parts on demand and build new weapons and crafts such as autonomous vehicles.

Find out more about Startup investing Benzinga.

Join Benzinga Pro to get real-time stock alerts. Try out the tool to help you invest faster and smarter.

This article 3D printing innovations in healthcare, construction and armed forces lead the way in 2023 originally appeared at Benzinga.com

.

© 2023 Benzinga.com. Benzinga does not provide investment advice. All rights are reserved.